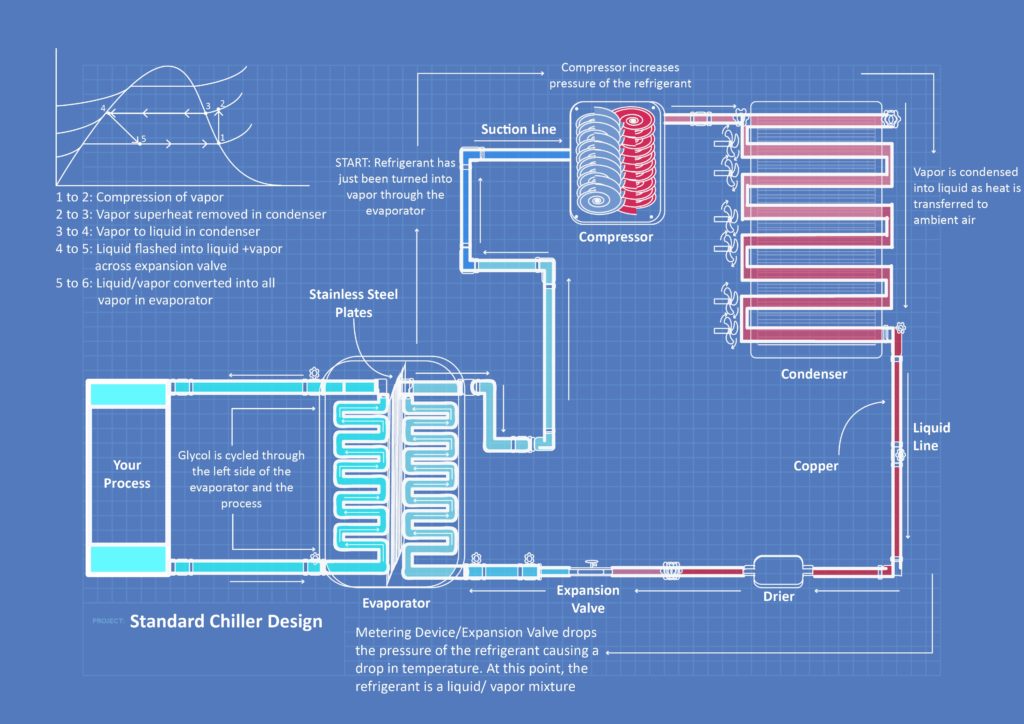

Description of a basic chiller refrigeration system: Starting at the compressor; the refrigerant is compressed and sent out of the compressor as a high temperature, high pressure, superheated gas. The refrigerant travels to the condenser (Which can be air cooled by fans or water cooled by tower or city water). The condenser changes the refrigerant from a high temperature gas to a warm temperature liquid. It then travels into a receiver (optional component). Then continues to the Thermal Expansion valve or TXV. The TXV meters the proper amount of refrigerant into the evaporator. The TXV takes the high pressure liquid and changes it to a low pressure cold saturated gas. This saturated gas enters the evaporator where it is changed to a cool dry gas (no liquid present). The cool “dry” gas then re-enters the compressor to be pressurized again. The “hot gas by pass” or unloader assembly is used to stabilize the cooling output of the refrigeration system by allowing hot gas to warm up the cool evaporator. This causes a reduction in the cooling efficiency and a stabilizing of the supply chilled water temperature. There are a few other unloader concepts that are used in refrigeration systems, but ideally accomplish the same outcome. There are also other specialized components that you may find on “your” chillers’ refrigeration lines; such as solenoid valves, a liquid site glass, accumulators or subcoolers. Go to www.chillers.com for more information.